Our Products

We offer a full size cover tapes with best quality

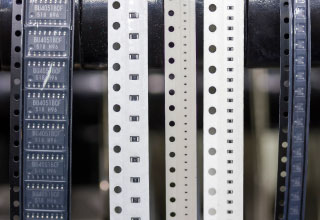

Anti-Static Cover Tape for SMD, SMT

The cover tapes(Tape & Reel) for semiconductor(IC) or Passive components is good for SMD/SMT(Surface-Mount Device / Surface-Mount Technology) process. And can anti-static cover tape for packaging of surface mount devices (ESD protection).

1. Transparent Type

2. Conductive Type(90%)

1. Anti-High Temperature Type

2. Transparent Type

3. Conductive Type(90%)

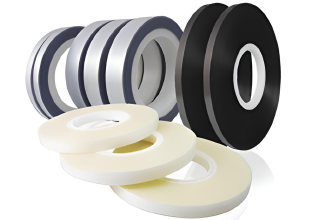

Heat Seal Cover Tape

High quality heat activated cover tape engineered specifically to meet IC/LED packaging requirement; 70 degree oven test heat resistance and compatible for sealing speed of 0.1/sec. For any heat-activated adhesive cover tape, as a general rule,increasing temperature, dwell time, and pressure on a given sealing machine will, within limits, increase adhesion (peel). However, for most of the HAA cover tapes available in the marketplace today, temperature and dwell will have a greater affect on adhesion than pressure. The ways these variables interact in the sealing process are of interest to anyone trying to control a packaging process.

Width: 5.4mm, 9.3mm, 13.3mm, 21.3mm, 25.5mm, 37.5mm, 49.5mm, 65.5mm, 81.5mm

PSA Cover Tape

PSA cover tapes ( Cold Seal Cover Tape ) is easier to seal than the heat activated counterparts. The PSA adhesive is a synthetic adhesive formulated to remain tacky over a wide range of temperatures, including room temperature. Hence, PSA cover tapes don't heat to seal them with carrier tape. PSA cover tapes are slightly more complex in their cons.

The cover tapes(Tape & Reel) for semiconductor(IC) or Passive components is good for SMD/SMT(Surface-Mount Device / Surface-Mount Technology) process. And can anti-static cover tape for packaging of surface mount devices (ESD protection).

Width: 5.4mm, 9.3mm, 13.3mm, 21.3mm, 25.5mm, 37.5mm, 49.5mm, 65.5mm, 81.5mm

Process Film

We offer a full size cover tapes with best quality

Anti-Static Cover Tape for SMD, SMT

The cover tapes(Tape & Reel) for semiconductor(IC) or Passive components is good for SMD/SMT(Surface-Mount Device / Surface-Mount Technology) process. And can anti-static cover tape for packaging of surface mount devices (ESD protection).

1. Semitransparent Type (80%)

2. Transparent Type

3. Conductive Type(90%)

1. Anti-High Temperature Type

2. Transparent Type

3. Conductive Type(90%)

Heat Seal Cover Tape

High quality heat activated cover tape engineered specifically to meet IC/LED packaging requirement; 70 degree oven test heat resistance and compatible for sealing speed of 0.1/sec. For any heat-activated adhesive cover tape, as a general rule,increasing temperature, dwell time, and pressure on a given sealing machine will, within limits, increase adhesion (peel). However, for most of the HAA cover tapes available in the marketplace today, temperature and dwell will have a greater affect on adhesion than pressure. The ways these variables interact in the sealing process are of interest to anyone trying to control a packaging process.

Width: 5.4mm, 9.3mm, 13.3mm, 21.3mm, 25.5mm, 37.5mm, 49.5mm, 65.5mm, 81.5mm

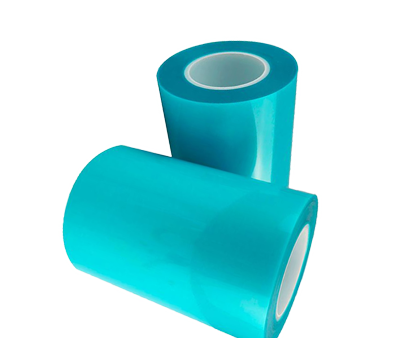

UV / Thermal Release Tape

UV Release Film(Dicing tape) can be released after UV curing the tape from a specific UV wavelength. So it can be applied on somewhere which you want to protect or fix your products, but need quick to release by UV curing. The adhesion of UV cure release adhesive before UV curing can be adjusted from 500g to 2500g. After UV curing, the adhesion can be reduced to less than 30g.

Thermal Release Film can be released the components after being heated to a proper temperature after the process is completed. Applied for stacking, cutting, flipping of multi-layer ceramic capacitors (MLCC) or other components. Especially in the work that can not be achieved by the UV release tape, it can often be done by thermal Release Tape. We still can customized development according to request.

About Us

We are producing the semiconductor tapes with highest quality and stable quality.

- High-Quality

- Reliable ESD Function

- Stability of Peeling Strength